Scribe Marking is Quiet Clear

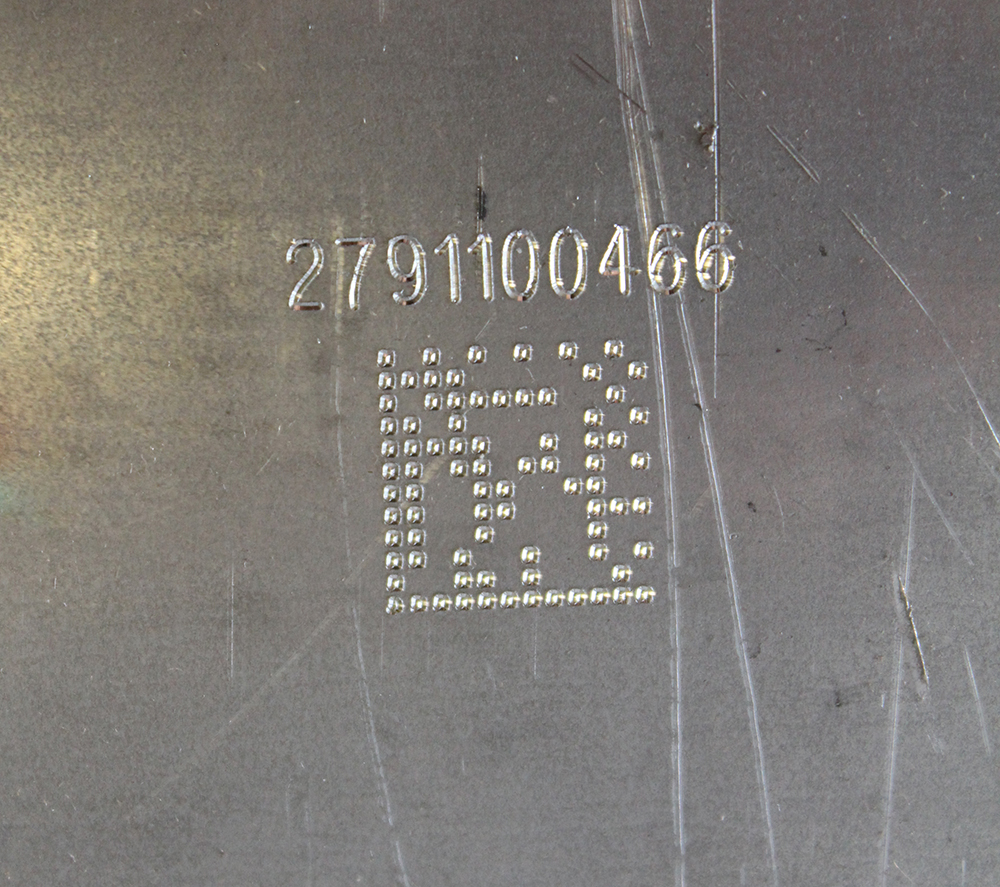

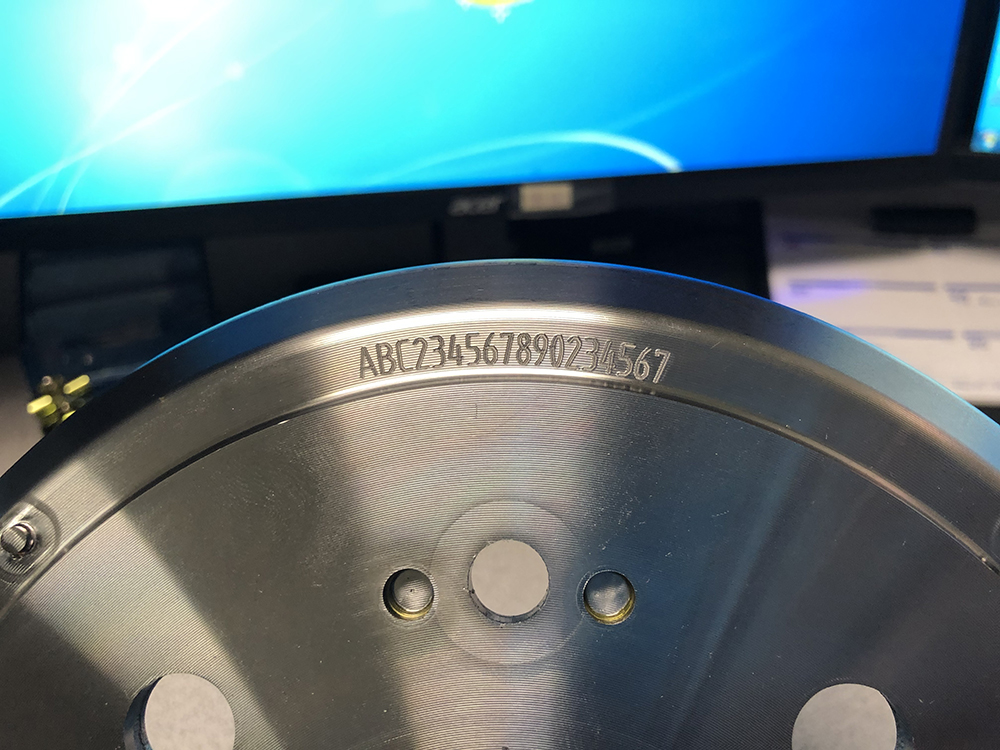

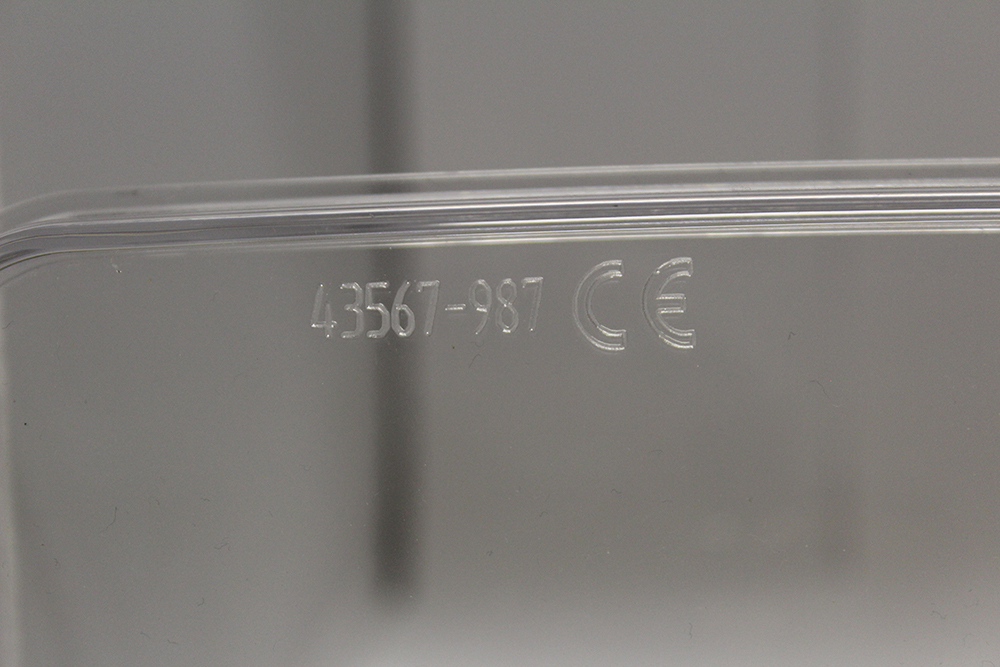

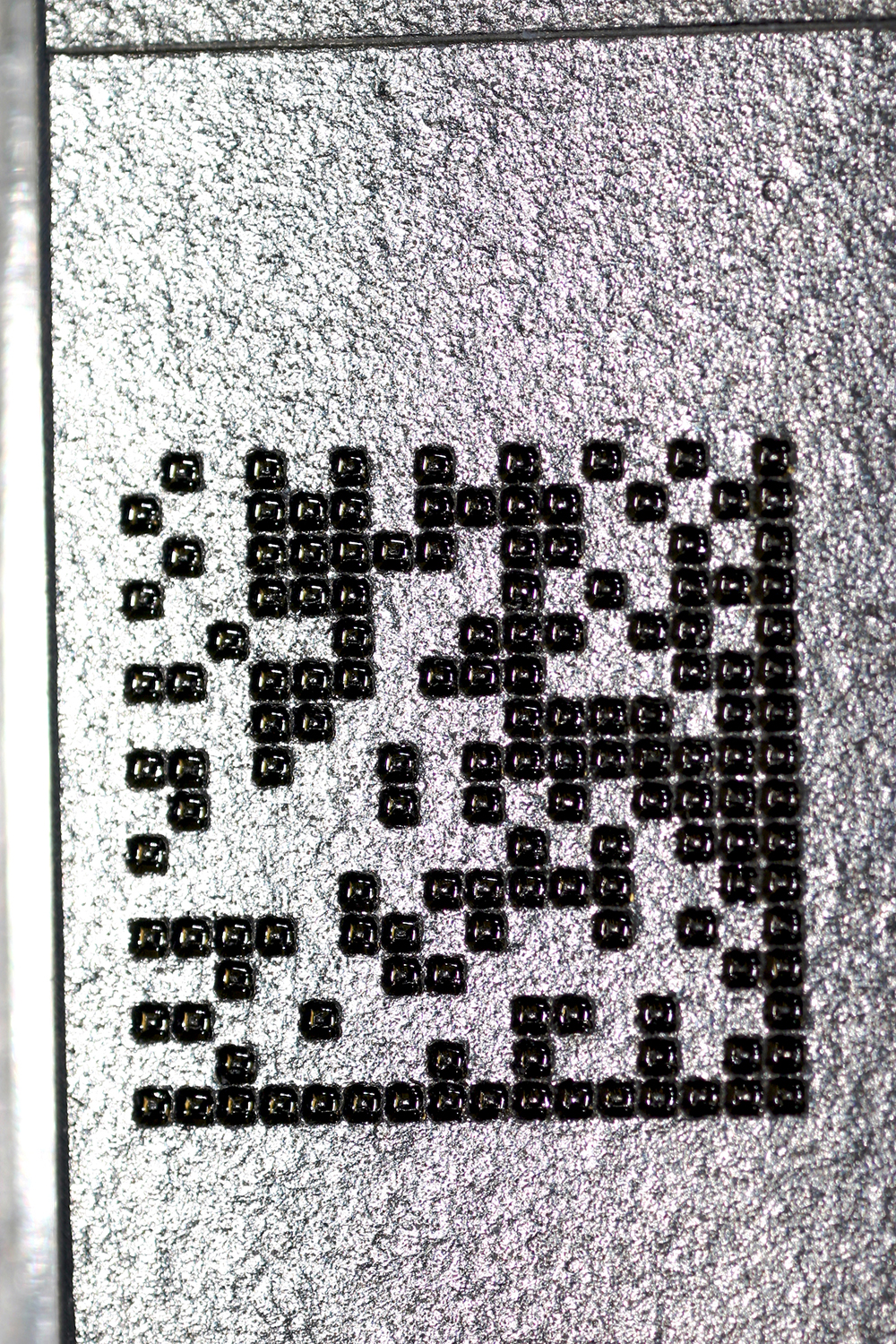

Scribe Marks

Scribe Machines

"Silent" scribe marking machine

The complete bench-top scribe marking system is offered in two versions: 1) standard for marking flats surfaces, 2) with a rotator for marking the OD of round parts. Options include: marking window sizes, push button cycle start, guarding and more. These systems are good solutions for moderate production marking requirements (250-750 part per shift).

Extreme heavy-duty construction

"Silent Scribe" version of the popular I-Series Dot Peen. This ball screw drive system has a marking speed of 3-5 characters per second in scribe mode. The system comes with two marking window options: 40 x 60 mm and 80 x 200 mm. This system is UID/2D Square-Dot® compatible. Advanced communications options include programming over LAN and operation controls via modbus, serial, Ethernet IP and more.

Ready for work in robotic automation production cells

Pedestal I-Mark station uses the I-Mark I Series high-volume production marking head combined with a sturdy pedestal for easy installation in a robotic automation cell. Options include: communication protocol, Z-axis, part touch-off and integrated camera

Twice the workload at an amazing savings

Expanded controller offers options including motion, axes or dual machine controls. All of the functionality of the I-Mark controller including the selection of communications options and the advanced networking capabilities.

Largest range of marking windows, speeds, and options to configure the most challenging applications

Versatile marking system offering both dot peen and "silent scribe" marking in the same system. This ball screw drive system comes with either stepper drive offering up to 4 characters per second, or a high-speed servo drive offering up to 8 characters per second. The system controller offers the flexibility of DC start and mark complete signals, as well as serial and digital I/O communication. This system is UID/2D Square-Dot® compatible. Advanced communications options include programming over LAN and operation controls via modbus, serial, Ethernet IP and more