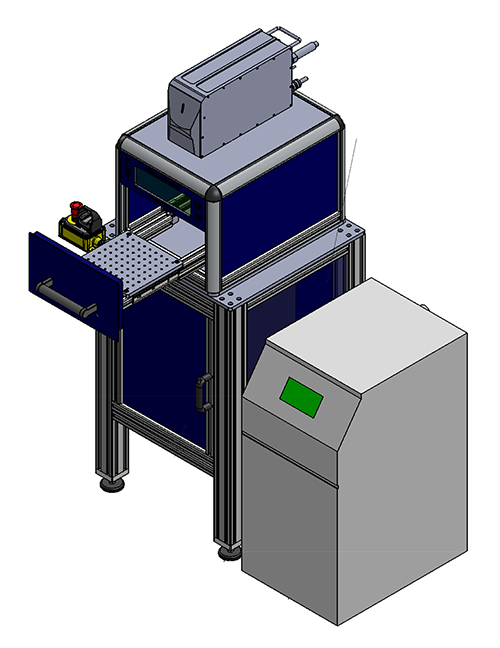

CMT Eclipse LE16HD Automated Compact Laser Marking Machine

CMT Eclipse Model LE16HD is designed for automated integrated robot loading/unloading industrial laser marking.

The CMT Eclipse LE16HD Automated compact model for robotic work-cell production laser marking of small parts. Check out included features and essential components to make a complete turnkey station.

Automated Enclosure

CMT Eclipse Model LE16HD is a compact laser marking machine designed for use in fully-automated robotic work cells.

Key Points:

Laser Source

CMT has a range of laser sources to meet any application requirement. From CO2 laser for plastic marking to high wattage fiber lasers with 3D profiling capabilities.

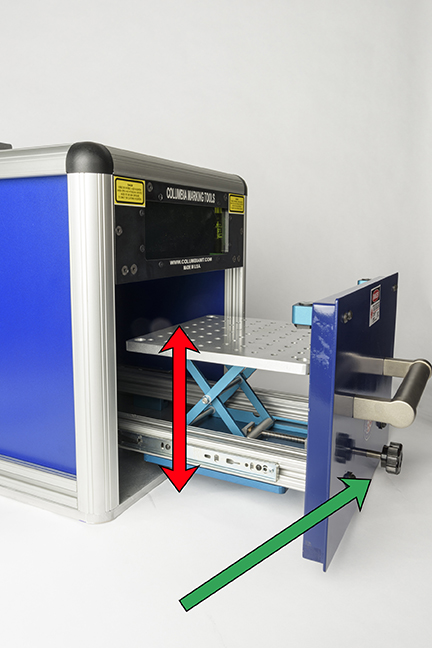

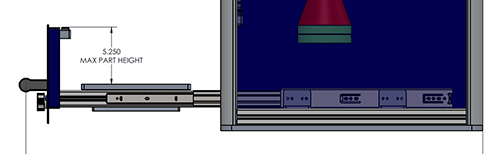

Work Area

The drawer will allow parts of to 5.25" tall through its compact opening. The fixture plate may be raised and lowered via the adjustment knob on the outside of the enclosure. Laser focal distance is also a factor in the maximum part marking height. The fixture plate has a size of 10" x 10" (250mm x 250mm).

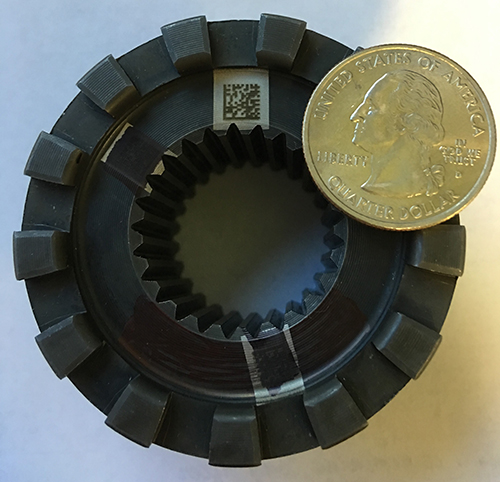

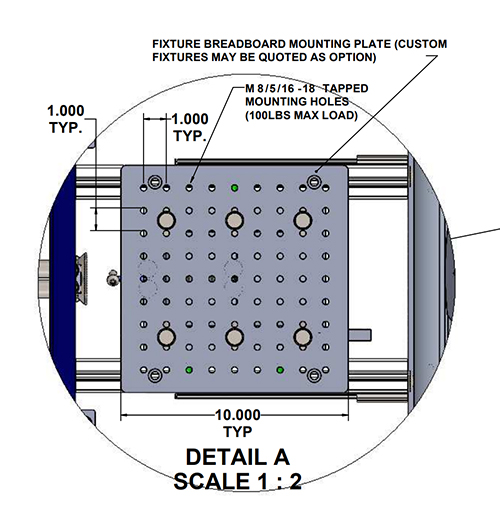

Fixture Plate

The CMT Eclipse LE16HD fixture plate is a 10" x 10" plate with evenly spaced holes to mount fixtures for the laser marking process. The mounting holes are spaced at 1" intervals. The standard breadboard has 5/16-18 tapped holes. A metric option is available upon request.

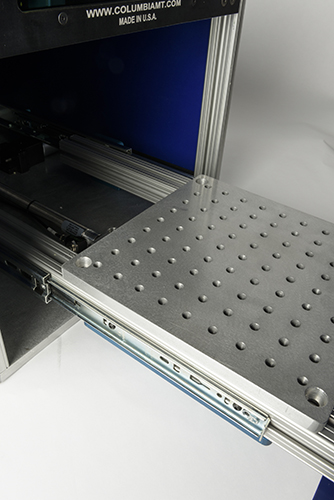

High-Speed Drawer

CMT Eclipse LE16HD is engineered and built for high volume/high-speed manufacturing. The high-speed drawer features:

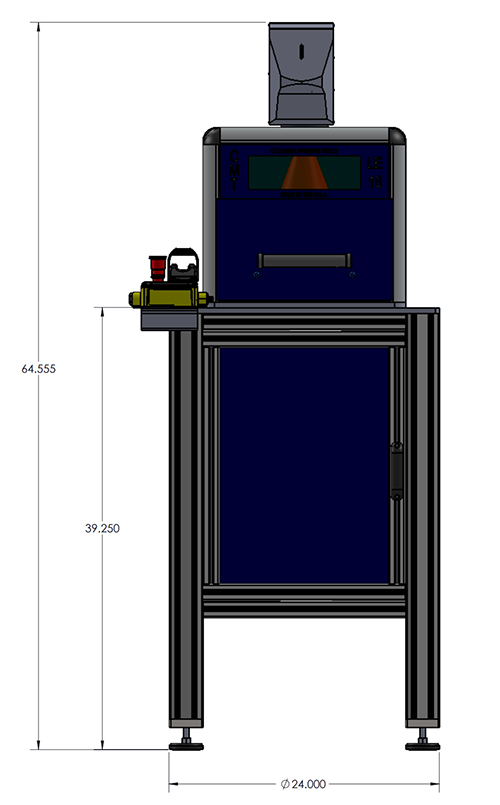

Floor style Base

Industrial machine base takes the LE16 from a bench top station to a complete floor style machine. The base has room to mount the laser controller and HMI PC. The base comes standard with leveling feet. Castor upgrades are available for station mobility.

Field bus Controls

All LE16HD automated laser systems come with a field bus/junction box

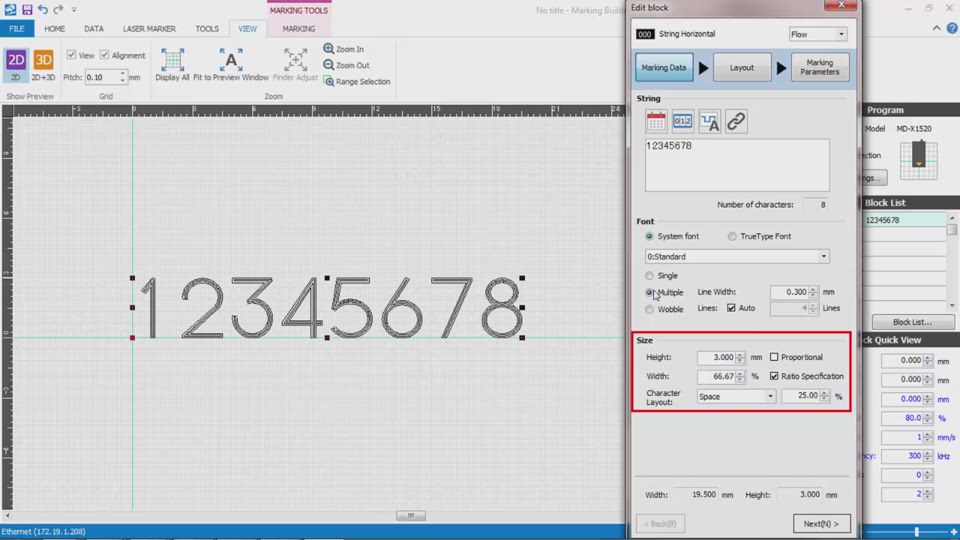

Laser Software

All laser sources come with Windows software. Features include:

All of the needed elements to have a complete turnkey marking station.

- I-Mark M and MS Series - included

- I-Mark C Series

- CMT Eclipse LE16 Compact

- CMT Eclipse LE24 Round

- CMT Eclipse LE48 Large Bed

- CMT Eclipse LER Rotary Turn Table

- CMT Eclipse Tunnel Automated Conveyor

A great addition to the I-Mark dot-peen and scribe marking machines or the CMT Eclipse laser marking machines is the CMT industrial PC. The Windows-based PC is a fanless computer with no moving parts. The complete upgrade includes: Windows software, preloaded laser software, 17" monitor and mount, membrane keyboard and shelf.

- CMT Eclipse LE16 Compact

- CMT Eclipse LE16HD Robot Station

- CMT Eclipse LE24 Round

- CMT Eclipse LE48 Large Bed

- CMT Eclipse LER Rotary Turn Table

- CMT Eclipse Tunnel Automated Conveyor

CMT offers an industrial fume extractor for laser marking. Laser marking is a burning process, and the smoke contains particulate matter that is not healthy for the operator to breathe. The smoke and particulate also impedes the laser beam and reduces the clarity and depth of the mark. A powerful fume extractor system is recommended to assure safety of the operator and the clarity of the mark.

The CMT Fume Extractor is contained in a brushed stainless steel floor-style cabinet with casters. The 3-stage filter system is pre-piped and wired to the laser enclosure system. The complete package includes hoses and suction nozzle mounting. CMT recommends this essential component to provide longevity to the laser unit investment.

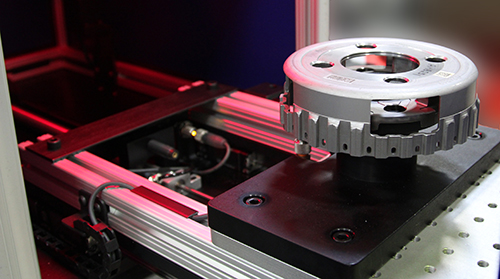

CMT can provide a custom designed master fixture plate with adjustable design and positive part stop for exact positioning every time. The application specific solution will be precision designed and built. CMT custom fixtures feature easy clamping or backup system to provide repeatable positioning. Please provide part prints with marking location noted at the time of quotation request.