I-Mark IM300 Dot-Peen and Scribe Marking Model IM300 provide cost savings. improved throughput. 4+ axis controls.

Dual Marking Heads

Control multiple marking heads with one controller. If two marking applications are close together, then the use of a double-headed system provides cost savings. Savings include 15-20% lower than the cost of two individual systems. In addition, there are lower installation and running costs - one controller to mount and integrate.

Application Examples

The I-Mark Mode IM300 has a choice of two I-Series marking heads. The I-Series has a selection of either dot peen or scribe marking pins and small or large marking windows. The applications for this unique marking system include:

More Possibilities

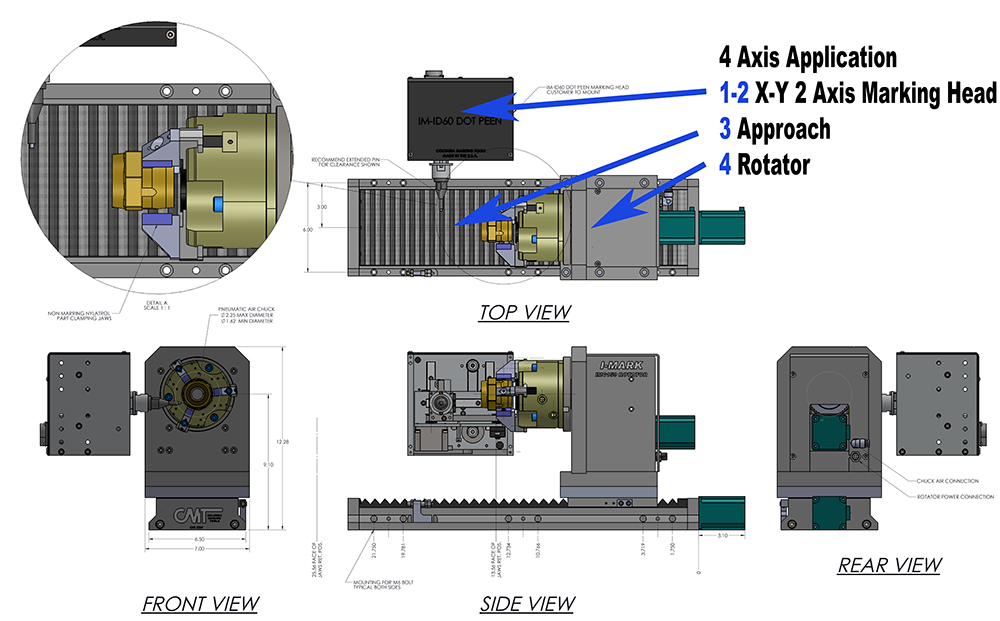

The 4-axis controller may be used to control 4 axes of any configuration. This example was designed for use in a CNC machining cell.

- X-axis I-Mark I Series

- Y-axis I-Mark I Series

- Z-axis part approach

- Rotator

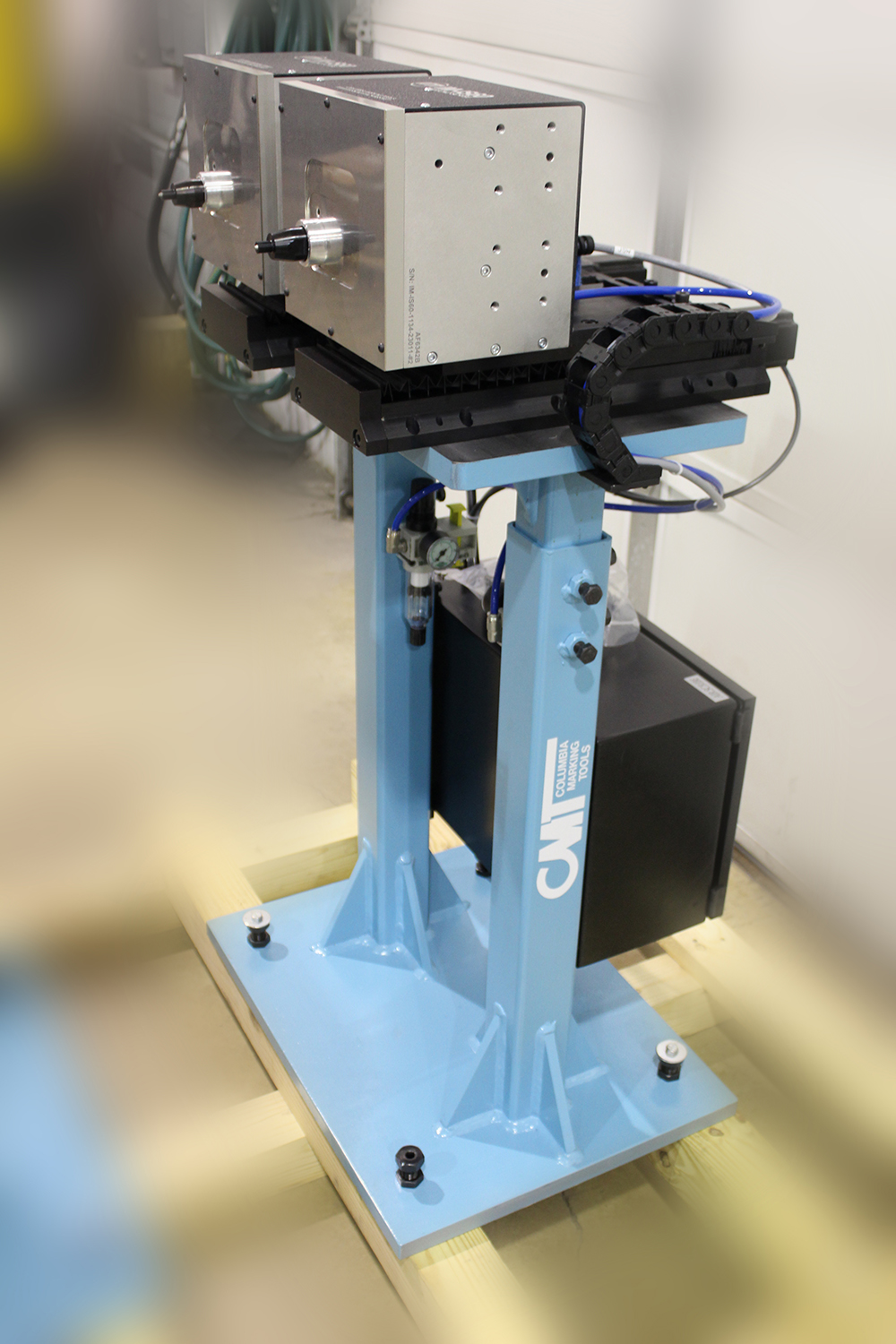

6 Axis Controls

The I-Mark IM300 can control a maximum of 6 axes. The example shown at right includes (2) 2-axis marking heads each with a completed programmable 6" approach stroke. This dual-headed marking station is used to maximize throughput on an automated conveyor system.