CMT custom-designed HMI can combine steps in the marking operation to save time. lower costs. improve quality.

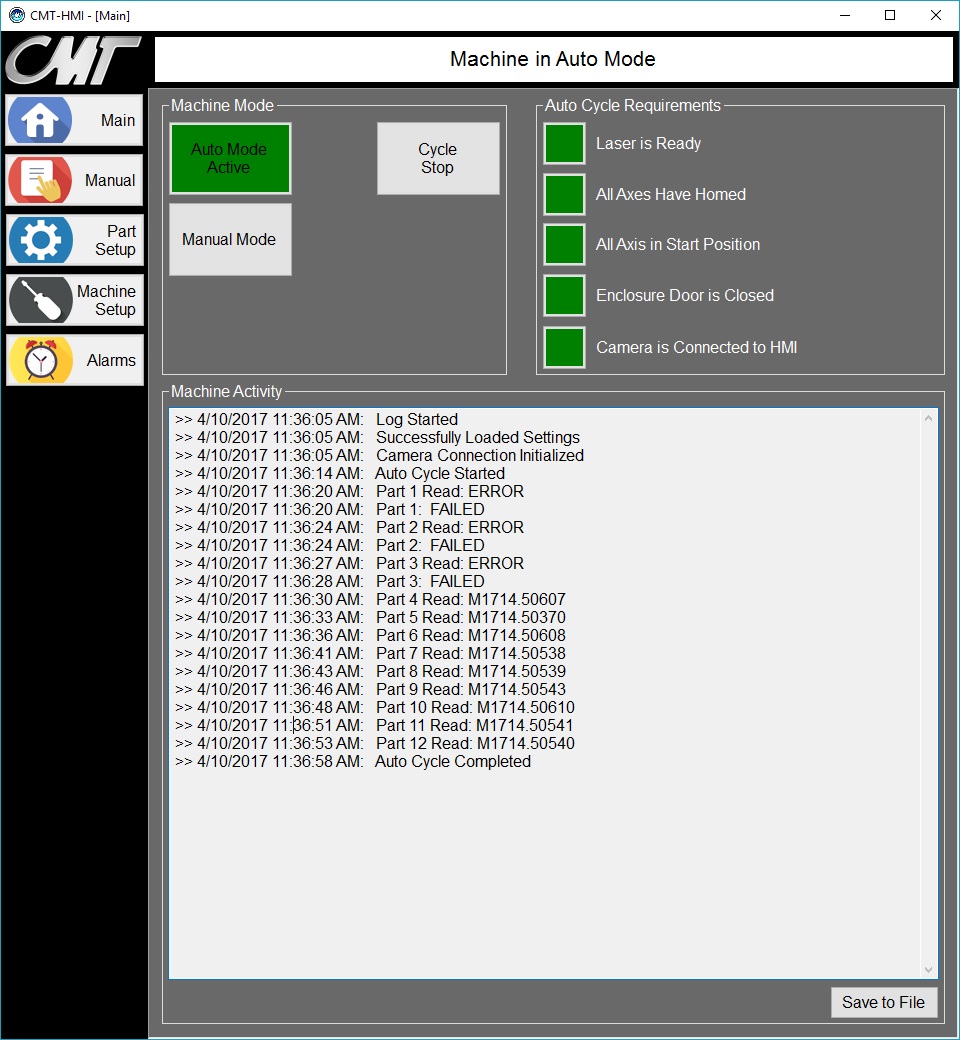

Automation Controls

Automated tag production machine controls are controlled by the CMT HMI. This system can be used to take data from a customer MES system and mark indentification tags. The CMT HMI also assures the proper function of the marking source which could be laser, dot peen, or scribe.

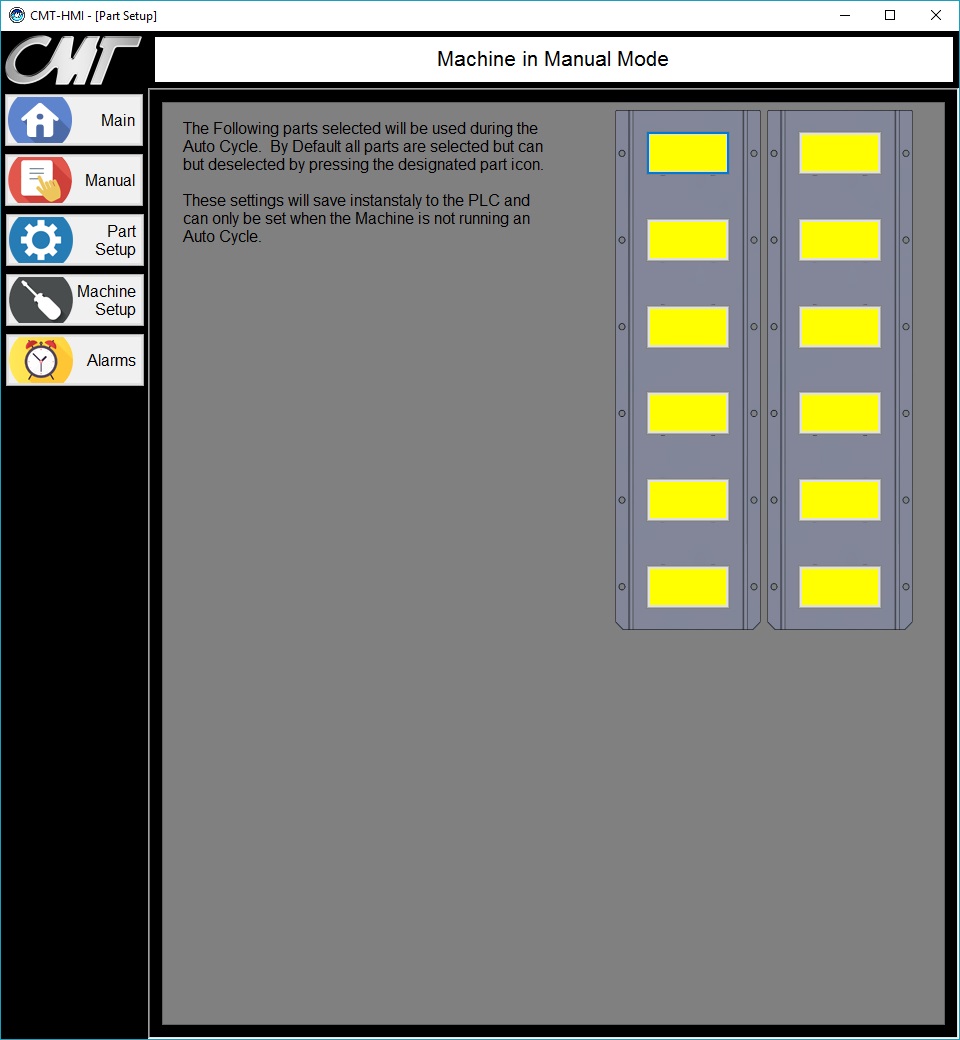

Flexible Functions

The CMT HMI can be used to change the machine function from automated to manual. This provides a flexible solution to be able to mark both select pieces and high-production parts with the same system.

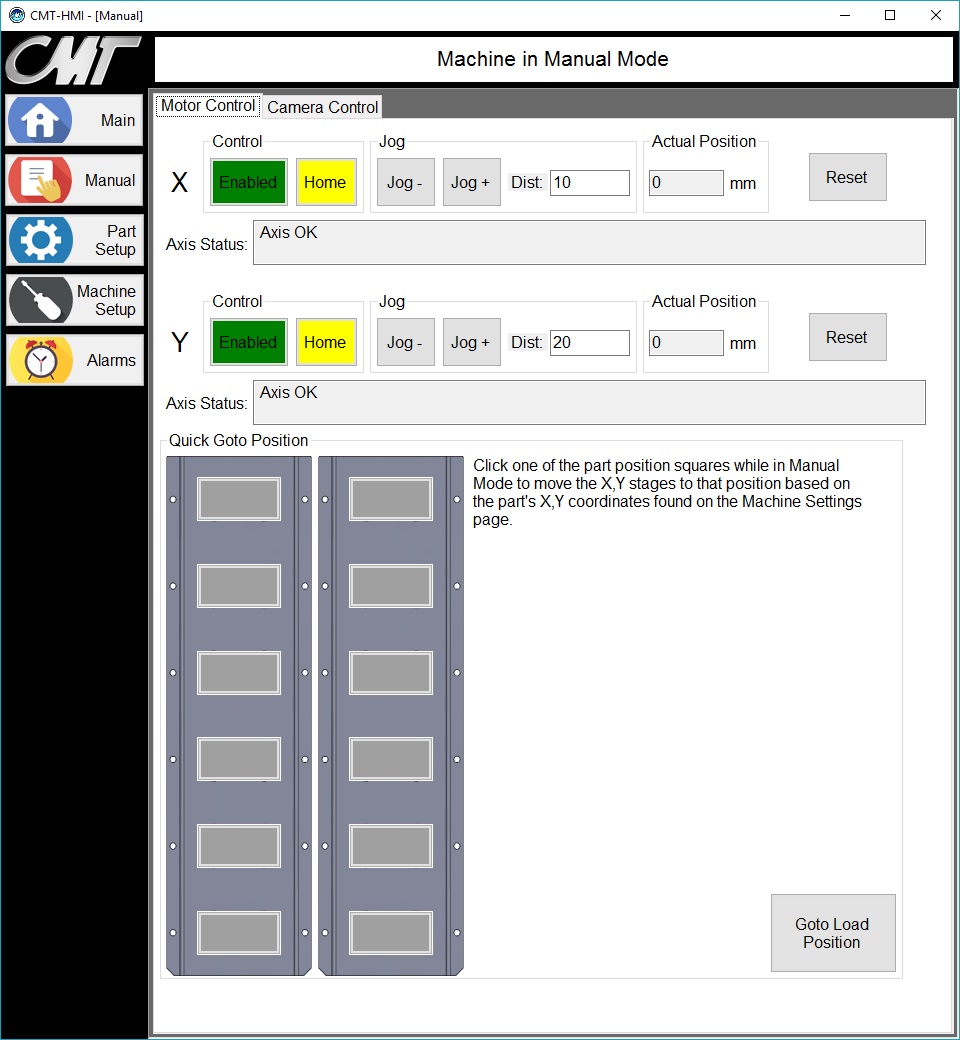

Axis Controls

The CMT HMI can combine multiple axes and other functions in a seamless interface. Applications include:

Error Proofing

CMT HMI can integrate camera systems with part marking. The camera can verify the part prior to marking, or the camera can read the 2D code and verify it as part of the marking process.

Safety and More

Safety requirements can be easily met with the addition of the CMT HMI. Additional safety locks and sensors can be cominbined into the safety circuit.